Views: 0 Author: Site Editor Publish Time: 2026-01-22 Origin: Site

How TPI, Tooth Profiles and Hook Angles Shape Every Cut

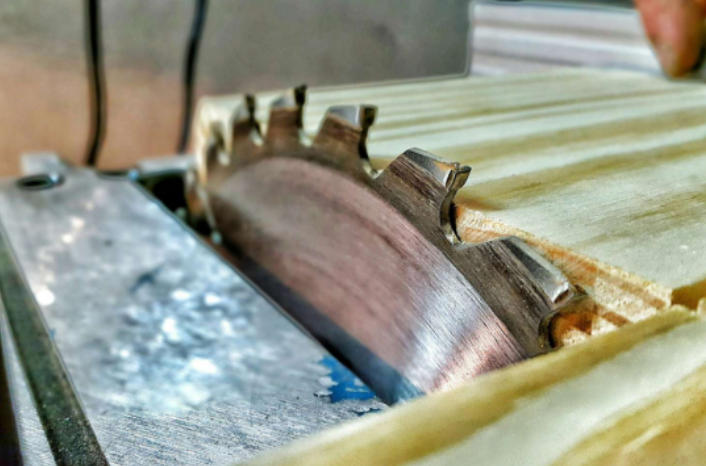

When you pick up a circular saw blade or a jigsaw blade, you're not just choosing a diameter or a brand. The number of teeth, the tooth shape and the tooth angle quietly decide three things that matter on every job: how fast you cut, how clean the edge looks, and how safe and stable the cut feels.

If you've ever wondered why one blade burns hardwood, another tears laminate to pieces, and a third sails through aluminium with a silky finish, the answer is almost always in the teeth. This guide walks you through the key ideas behind saw blade teeth and shows you how to match TPI, tooth profile and hook angle to the material, the machine and the cut you need.

Before we dive into details, it helps to see the big picture. For most woodworkers and fabricators, a saw blade's cutting behaviour comes down to three main levers:

•TPI (Teeth Per Inch) – how many teeth are working in each inch of the blade

•Tooth profile – the shape and grind of each tooth (ATB, TCG, demolition, etc.)

•Hook angle – the angle the tooth leans forward or backward into the material

Once you understand how each of these affects speed, finish and control, choosing the right blade becomes much more straightforward.

TPI is simply the number of teeth the blade has per inch. Blades with a low TPI have fewer, more widely spaced teeth; blades with a high TPI pack more teeth into the same distance.

For wood and other soft materials, a TPI from 6 up to 20 is typically suitable. Lower values in this range favour fast, aggressive cuts such as ripping framing lumber or rough dimensioning. Higher values push you towards smoother cuts on plywood and softwood trims.

For harder materials like metal, you need more teeth engaged at any moment to avoid snagging and tooth breakage. A TPI between 14 up to 36 is more suitable for these applications, helping each tooth take a smaller bite and distribute the load more evenly.

You don't have to guess the TPI: the number of teeth is normally marked directly on the blade or printed clearly on the packaging, often alongside other specs like diameter, kerf and bore size. Learning to read these markings is the first step to choosing intelligently instead of just grabbing "whatever is on the shelf".

The short answer is: more teeth usually mean a smoother cut, but not always a better choice.

Generally, the higher the amount of saw blade teeth, the better the quality of cut and surface finish. A high-tooth-count blade takes smaller bites, leaving fewer and finer machining marks on the edge. If you're crosscutting hardwood trim, cutting aluminium profiles or chasing a high-quality finish on laminate, you will usually want a blade with more teeth compared to blades intended for rough cuts in soft wood.

However, the trade-off is speed and chip evacuation:

•Fewer teeth mean deeper gullets – the spaces between teeth – which can carry away more chips. This creates a more aggressive chiselling action, allowing the blade to move quickly through the material. It's ideal when you're ripping softwood, cutting construction timber or making rough openings where finish matters less than productivity.

•More teeth reduce gullet size and chip load per tooth. That's great for clean cuts but can cause the blade to load up, run hotter and cut more slowly if you push too hard or work in thick stock.

If you're cutting aluminium or want a very high quality finish on laminate, a fine-tooth blade makes sense. If you're breaking down framing lumber all day, a coarse-tooth blade will feel more powerful, run cooler and put less stress on both saw and operator.

The key is to choose tooth count based on material + cut type, not just the promise of "finer" or "faster" in isolation.

Tooth count tells you how many teeth you have. Tooth profile tells you what each tooth actually does. Not all teeth are shaped the same. Different tooth geometries change how the blade enters the material, how it clears chips and how long it stays sharp.

Choosing the right tooth profile to match the material and desired finish can transform how a blade behaves on the same saw.

Alternate Top Bevel (ATB) teeth are bevelled on the top, with every other tooth bevelled in the opposite direction to its neighbour. One tooth scores and cuts primarily on one side of the kerf, the next tooth handles the other side. This alternating action shears fibres rather than simply tearing or scraping them.

Blades with ATB teeth are straightforward to re-sharpen and are commonly used as general-purpose woodworking blades.

•Ideal for: cross-cutting solid woods and veneered plywood, trim work and many general carpentry tasks where a clean edge matters.

•Practical tip: within the ATB family, a higher tooth count provides a finer cut. If you mainly do fine crosscuts or work with delicate veneers, choose an ATB blade with more teeth. For mixed ripping and crosscutting in construction lumber, a moderate tooth count is often more versatile.

Triple Chip Grind (TCG) alternates trapezoidal teeth with flat-top teeth. The trapezoidal tooth cuts first, breaking and scoring the surface; the following flat-top tooth then cleans out chips and slightly widens the cut. This combination spreads wear over more surface area and resists chipping at the corners.

TCG blades are built for heavy-duty, abrasive, or hard materials and can also be re-sharpened.

•Ideal for: very hard and abrasive panels like coated chipboards (HDF / MDF), laminates and non-ferrous metals such as aluminium. This tooth form delivers very clean cuts on laminate flooring, worktops and metal profiles while standing up well to high feed rates and tough surfaces.

Demolition-type blades use a more complex cutting material and a robust tooth geometry designed for survival rather than elegance. Here, safety and durability come first.

•Ideal for: cutting poor quality chipboard, subflooring and wood that may contain loose knots, screws or nails.

•These blades often incorporate anti-kickback features, such as specially shaped shoulders and a chip limiter at the back of the tooth shoulder that restricts the maximum tooth bite. By limiting how deeply each tooth can grab, the blade maintains a safe feed speed and reduces the risk of sudden stalls or kickback.

For added safety, ripping blades for wood and composites in larger diameters also use this type of design. Because these blades feature large tooth bites – the distance between two aggressive teeth – they must be used on machines equipped with appropriate safety features, such as a chip limiter system, to keep feed rate under control and prevent dangerous kickback.

Circular saw blades typically spin at high speed and follow straight lines. Jigsaw and recip blades, on the other hand, move in a rapid up-and-down stroke and often follow curves. The tooth design therefore needs to control both cutting and tracking in a very different way.

Here are the most common jigsaw tooth profiles and how they behave.

Milled teeth are formed with a less finely sharpened edge. Rather than slicing cleanly through fibres, they tend to tear them. This makes the blade more aggressive but also rougher in the finish it leaves.

As the blade travels up and down, the set of the teeth leaves visible marks on the cut edge. The result is a faster but noticeably rougher cut.

•Ideal for: metal and denser materials where longevity and cutting speed are more important than a perfectly smooth edge. Milled blades generally last longer under tough conditions than very fine ground blades.

In a wavy set design, groups of teeth are bent in a subtle wave pattern instead of simply alternating left and right. This wave maintains continuous surface contact between blade and material, helps the blade track straight and reduces jolting or snagging.

•Ideal for: cutting thin sections such as sheet steel, thin aluminium or plywood, where you want a controlled, straight cut and need to avoid catching or deforming the workpiece.

Ground teeth are precision sharpened with a very straight alignment. The cutting edge of each tooth is perpendicular to the cutting axis, and each tooth works over its full width.

This geometry allows the blade to slice cleanly through fibres and leaves a fine, sharp and very clean cut with minimal tearing.

•Ideal for: softer materials such as chipboard and softwood, where you want a clean edge and are prepared to trade some cutting speed for better finish.

In a ground side set design, the teeth are both ground sharp and set to the sides according to an oblique angle. This enables the blade to cut aggressively while still clearing chips efficiently.

•Ideal for: cutting wood at high speed, especially when you need to move quickly along curves or long cuts and can accept a slightly rougher edge in exchange for productivity.

The direction in which a tooth leans into the cut is known as the hook angle (or rake angle). Imagine drawing a line from the centre of the blade to the tip of a tooth; the hook angle is the angle between that radial line and the face of the tooth.

•A positive hook angle means the tooth leans forward into the material. The more positive the hook angle, the more aggressively the saw blade pulls itself into the cut. This is excellent for moving through a lot of material quickly, particularly when ripping along the grain in solid wood.

•A low or negative hook angle means the teeth lean backwards, away from the direction of rotation. This makes the blade less grabby, more controlled and better suited to crosscutting, cutting thin panels or working with brittle or non-wood materials.

Low (negative) hook angles are good for crosscutting, cutting plywood panels or handling non-wood materials such as plastics and metal. If you're cutting plywood, MDF, OSB, laminate, melamine boards or particleboards, an angle between -2° and -10° is generally recommended. This helps reduce chipping on the face layer and gives you more control as the blade enters and exits the workpiece.

Once you understand TPI, tooth profiles and hook angles, choosing a blade becomes a matter of following a clear process. By deciding how many teeth you need and which tooth shape is appropriate, you can select a blade that gives the finish you want without slowing down the job.

Follow these four steps to narrow down your options.

Start with what you're actually cutting. Solid softwood, hardwood, veneered plywood, MDF, OSB, laminate flooring, melamine boards and particleboards all behave differently at the tooth edge.

Once you know the material, you can align it with the appropriate product family or colour-coded range and focus only on blades designed for that category instead of comparing every blade on the shelf.

Next, decide which machine the blade will be fitted to: a handheld circular saw, table saw, mitre saw, track saw, jigsaw or another type. Product information is often grouped by machine type for this reason.

A blade that works beautifully on a table saw may be a poor match for a compact cordless circular saw, either because of weight, kerf or required power. Choosing by machine type keeps you within the safe operating limits of your equipment.

Check the specifications of your machine for the required blade diameter and bore size (or shank type for jigsaw blades). Only blades that match these dimensions are suitable.

On circular saws, product dimensions are usually easy to find beneath each product line in catalogues or product pages – for example, a diameter of 165 mm with a 20 mm bore. Using the correct size ensures the blade fits securely, runs true and can reach the designed cutting depth.

If an adapter such as a reduction ring is necessary, make sure it is high quality and fits the bore of your blade perfectly, with no play or misalignment.

Finally, think about the type of cut you need to achieve:

•Ripping along the grain, where feed speed and chip removal are priorities

•Crosscutting, where a clean edge with minimal tear-out is more important

•Finishing cuts in visible surfaces such as laminate, veneered panels or trim

For faster, rougher cuts, choose a lower tooth count with deeper gullets and an aggressive tooth form. For finer work, step up to a higher tooth count and a tooth profile optimised for clean shearing, such as ATB or TCG.

You can also look at the key specification data beneath each product line in a catalogue or online listing. These usually include tooth design information and intended cut type, helping you quickly confirm whether a blade is tuned for ripping, crosscutting, finishing or demolition work.

The right blade can only perform at its best if it's used and maintained properly. Good safety habits and regular maintenance improve cut quality and significantly extend blade life.

When working on wood materials, it's wise to wear at least a dust mask and safety glasses, and to add ear protection and gloves during heavy-duty usage. A vacuum extraction unit or dust collection system helps remove shavings and debris, keeps the cut line visible and reduces airborne dust.

Before using any blade, systematically and carefully check your machine and blade condition:

•Look for cracks, missing teeth, heavy pitch build-up or obvious damage.

•Ensure the blade is tightened correctly and runs without noticeable wobble.

•When using a reduction ring or adapter, thoroughly check its quality and ability to fit the bore of your blade perfectly.

Cleaning your blades regularly – ideally after every use, but at least on a consistent schedule – helps prevent resin and pitch from building up on the teeth. This build-up makes the blade run hotter, increases cutting resistance and degrades the quality of cut long before the teeth are truly worn out. A clean blade cuts cooler, straighter and lasts longer.

If you're new to working with different wood types, it can also be helpful to start with a basic overview of softwood, hardwood and engineered panels so you know what demands each material will place on your blade. When in doubt about which blade to choose for a tricky job, consulting an experienced technician or tooling expert can save you time, money and frustration – and ensure you're working as safely and efficiently as possible.