Views: 0 Author: Site Editor Publish Time: 2026-01-12 Origin: Site

If your circular saw "never quite cuts straight", the issue is usually not your pencil line or tape measure—it's the blade. More specifically, the blade isn't square to the shoe of the saw. Learning how to square the saw blade is one of those small setup skills that quietly decides whether your cuts are clean and accurate or always a little off.

When we talk about a square blade here, we mean a blade that has been adjusted so it sits at a perfect 90-degree angle to the shoe. Once you get that relationship right, your circular saw starts acting less like a rough demolition tool and more like a precise square saw for everyday carpentry.

Think of the goal as a kind of square circular setup: a circular saw that reliably makes true, square cuts instead of leaning a degree or two in either direction.

On a circular saw, the blade is mounted in a housing that pivots relative to the shoe (base plate). The bevel mechanism lets you tilt the blade for angled cuts, but at the "0°" setting it should be exactly perpendicular to the shoe.

When the blade is properly squared:

•The blade's body is at a true 90° angle to the shoe.

•The shoe can sit flat on your workpiece, giving you a stable reference surface.

•A square placed on the shoe touches the blade perfectly with no gaps.

When it's not squared, you've still got a flat blade saw in appearance, but every cut leans slightly. You feel it when pieces don't meet cleanly and "square" joints mysteriously show daylight at one edge.

You can picture the relationship between the blade and the shoe like a circular square—a straight reference edge (the shoe) and a circular cutting edge (the blade) that have to meet at a perfect right angle.

Most people first notice something is wrong when they're cutting wood circular saw style on simple projects: shelving, framing, face frames, worktops. The line looks good from above, but when you stand the board on end, the cut clearly leans.

An out-of-square blade can cause:

•Crosscuts that lean inward or outward when you want a straight vertical face

•Joints that never quite close, even when your measurements are technically correct

•Extra trimming, sanding, or re-cutting to correct small but annoying angles

•Wasted material and a general feeling that the saw can't be trusted

Because the error is built into the tool's geometry, every cut carries the same mistake. That's why taking time to square the blade is so powerful: once fixed, all your basic cuts improve at once.

You don't need expensive instruments to square a blade properly. A handful of reliable basics are enough:

•Your circular saw

The process is the same whether it's a new cordless model, a compact circular skill saw, or an old Dewalt circular saw or old Milwaukee circular saw that's been in your shop for years.

•Layout square or combination square

This is your main reference for 90 degrees. You'll rest it on the shoe and bring it up to the blade to see whether the blade is truly square.

•Speed square

Helpful later for test cuts and as a straight guiding fence. Many people use a speed square circular saw setup for quick, accurate crosscuts once the blade is squared.

•Allen wrench

Used to adjust the bevel stop set screw, so that the "0°" mark actually corresponds to a perfectly squared blade. The exact size depends on your saw.

•Skill saw blade wrench (or the wrench supplied with your saw)

This is what you'll use on the arbor bolt when you need to remove or tighten the blade. People often search for things like how to tighten skill saw blade or how to tighten circular saw blade, and this is the tool that makes it easy.

•Flat, stable surface

A workbench, table, or sheet of plywood that doesn't flex or rock. A flat surface makes it much easier to see small gaps when you place a square.

•Safety glasses

You'll be very close to the blade and will likely make a few test cuts later. Protective eyewear should always be part of the routine.

Once these tools are gathered, you're ready to start the actual squaring process.

Before you touch any adjustments or bring a square near the blade, slow down and set up safely.

1. Disconnect power

Unplug the saw or remove the battery. Never adjust the blade or bevel with the tool powered.

2. Set bevel to zero

Unlock the bevel lever or knob and move the indicator to the 0° mark, then lock it again. The whole point of squaring is to make sure that "0°" really does mean square.

3. Lower the blade fully

Use the circular saw depth adjustment to extend the blade as far below the shoe as it will go. This gives you more flat blade surface to reference against with your square and makes alignment easier to see.

4. Place the saw on a flat surface

Set the shoe flat on your workbench or panel. If the saw rocks noticeably, the shoe may be bent, and you'll have a harder time getting a true reading.

At this stage you haven't changed alignment yet; you've just created a safe, controlled starting point.

Now you'll see how close the saw already is to being square.

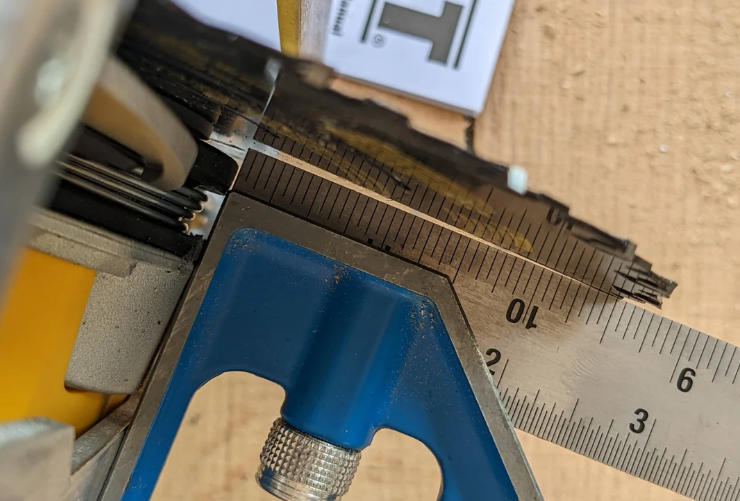

1. Position the square on the shoe

Set the short leg of your layout or combination square flat on the shoe, with the longer leg rising up alongside the blade.

2. Avoid the teeth

Slide the square until it touches the smooth body of the blade, not the teeth. The teeth are ground at angles, so if your square rests on them, you'll get a wrong reading.

3. Look for gaps

In good light, look at the line where the square meets the blade. If the square touches the blade evenly along its length, the blade is square. If you see a sliver of light between them at the top or bottom, the blade is tilted.

4. Check more than once

Rotate the blade slightly by hand (with the saw still unplugged) and repeat the check at a few different points. This helps you see whether the blade itself is straight.

If everything already looks perfect, you're lucky. Most of the time, you'll see a small gap and need to move on to adjustment.

The bevel stop is what tells the saw where "0°" actually is. If that stop is off, your blade won't be square no matter how carefully you set the scale.

1. Find the bevel adjustment set screw

This is typically near the bevel pivot, close to where the shoe attaches to the motor housing. It controls how far the shoe can tilt when you set the bevel to zero.

2. Loosen the bevel lock slightly

Unlock the bevel adjustment so the shoe can move very slightly relative to the motor. You don't want it floppy, just free enough to respond to the set screw.

3. Turn the set screw with the Allen wrench

Make very small adjustments. A quarter turn can move the blade noticeably. Turn one way and the blade will tilt toward the shoe; turn the other way and it will tilt away.

4. Lock and recheck

After each tiny change, lock the bevel again, set the square on the shoe, and bring it against the blade body. Check for gaps.

5. Repeat until the blade is square

Continue this small "adjust–lock–check" cycle until the square sits flush against the blade with no visible gap along the length of the contact area.

It's normal for this process to take several tries. Once you're done, your 0° bevel setting should correspond to a genuinely squared blade.

Since you're already working closely around the blade, it's a good time to double-check two simple but important details: direction and tightness.

Many beginners wonder which way does a circular saw blade go or think about the direction of skill saw blade rotation. The answer is straightforward:

•The teeth at the front of the saw should move down into the wood as you cut.

•Most blades have an arrow showing the correct rotation. Most saws also have an arrow on the guard or housing. Those arrows should match.

If the blade is mounted backwards, the saw will cut poorly and can be harder to control. Squared geometry won't help much if the blade itself is spinning the wrong way.

A blade that isn't snug on the arbor can wobble and undo all your careful squaring work. That's where the skill saw blade wrench or the wrench supplied with your saw comes in.

Here's the basic routine that answers both how to tighten circular saw blade and how to tighten skill saw blade in practice:

1. Lock the spindle or arbor using the saw's lock button (if provided).

2. Place the wrench on the arbor bolt.

3. Tighten the bolt firmly until the blade is secure and there's no side-to-side movement.

4. Spin the blade by hand to make sure it turns freely and doesn't rub any part of the guard.

Once the blade is correctly oriented and tight, your squared adjustment can do its job consistently.

After squaring the blade, it's smart to test it under real cutting conditions. A speed square makes this easy and also helps you get cleaner cuts in daily use.

1. Mark a straight line across a piece of scrap.

2. Hook the lip of the speed square over the edge of the board.

3. Set the front of the shoe against the speed square, creating a speed square circular saw guide.

4. Make the cut slowly and steadily.

When you look at the cut from the end, the freshly cut face should be at a true 90° angle to the surface of the board. If the blade is truly square, the offcut will stand upright without leaning. This quick test tells you whether the setup holds up when the saw is actually working.

Once you get used to this method, it turns your ordinary circular saw into something that behaves much more like a reliable square saw for straight, accurate crosscuts.

Even after you've squared the blade carefully, the setting can drift over time. Regular use, bumps, and storage can nudge things out of alignment, especially if the saw is used in rough environments.

To keep your blade square:

•Check alignment regularly

Before starting a new project or if the saw has been dropped or transported, take a minute to put a square on the shoe and check the blade again.

•Handle and store the saw carefully

Don't toss the saw onto piles of offcuts or hardware. Treat it like a small precision tool. Even a sturdy old Dewalt circular saw or old Milwaukee circular saw can lose accuracy if the shoe gets bent.

•Keep the shoe and blade clean

Pitch and sawdust can build up where parts meet, which may affect how the saw locks and sits on the workpiece. A clean tool is easier to read and keeps its settings better.

•Mark your "true zero"

Once you know the blade is perfectly squared at zero, you can lightly mark the correct position on the bevel scale or housing. If you tilt the blade for bevel cuts later, this mark gives you an easy reference to come back to.

These habits mean you don't have to completely relearn how to square the saw blade every time; you're just verifying that your earlier work is still holding.

Even with careful setup, a few recurring problems can get in the way of a perfectly squared blade. Here are some of the most common and what they usually mean.

If your blade keeps drifting out of alignment after you've squared it:

•The bevel adjustment might not be locking firmly.

•The bevel stop set screw may be worn or damaged.

•The shoe itself could be slightly bent.

In such cases, no amount of fine-tuning will fully fix the problem until the worn or damaged part is repaired or replaced.

If every turn of the Allen wrench seems to move the blade too much:

•Try gripping the wrench closer to the head to make finer movements.

•Think in eighth-turns or less, rather than full or half turns.

•Make sure the saw is resting flat and isn't rocking while you adjust and check.

Small angle changes will naturally feel sensitive, but slowing down and working in tiny increments makes it manageable.

If your square seems to give a different answer every time:

•Check that your layout or combination square is accurate.

•Clean dust and debris off the shoe and blade body before each check.

•Always reference the same part of the blade body, avoiding teeth.

•Use good lighting so you're not mistaking shadows for gaps.

Once these factors are controlled, your alignment checks become much more reliable.

Accuracy is important, but it never comes before safety. Keep these points in mind throughout the process:

•Always disconnect power before touching the blade or any adjustment.

•Wear safety glasses whenever you are near or using the saw.

•Be aware of sharp edges on the blade, even when it's not moving.

•Keep the work area clean and well lit, especially when you're trying to see small gaps between blade and square.

•Follow the instructions and diagrams provided by your saw's manufacturer for specific adjustment points.

A properly squared blade actually helps with safety too, because a saw that tracks straight and doesn't bind in the cut is easier to control.

Squaring the blade of a circular saw is not complicated, but it does require patience and a bit of care. Once you know how to square the saw blade—by checking with a square, adjusting the bevel stop, confirming direction and tightness, and verifying your results with real cuts—you turn a basic circular saw into a tool you can trust.

Whether you're working with a brand-new model or a well-used circular skill saw, the goal is the same: a blade that is truly square to the shoe, cuts that are straight and clean, and a setup you can rely on project after project.