Views: 0 Author: Site Editor Publish Time: 2026-02-24 Origin: Site

Cutting concrete sounds simple until you are actually standing on site with a deadline, a slab in front of you, and several different saws to choose from. A hand-held concrete saw is often the fastest way to open a doorway, cut a trench, or remove a damaged section of slab—but the tool you pick will decide how clean the cut is, how long it takes, how much you spend on blades, and even whether the job can be done at all.

In practice, most contractors are choosing between three families of hand-held tools:

•Center-drive cut-off saws with a circular diamond blade

•Ring saws with an edge-driven ring blade

•Diamond chainsaws with a bar and chain

Each type has a specific role. Understanding their strengths and limitations is far more important than memorising model numbers. This guide walks through how each saw works, where it shines, and how to decide which hand-held concrete saw makes the most sense for your next job.

All modern concrete saws do essentially the same thing: they use industrial diamonds bonded to a metal matrix to grind their way through hard materials. The motor doesn't "slice" concrete like a wood saw; instead it spins or drives the diamond segments at high surface speed so they slowly erode the aggregate and paste.

From a practical standpoint, three factors matter more than anything else:

1. Depth of cut – how far into the material the saw can reach

2. Access – whether you can reach from one side or both, and how much space you have

3. Cost per metre of cut – the real-world cost of blades or chains, not just the price of the tool itself

Center-drive cut-off saws, ring saws, and diamond chainsaws approach these three factors in different ways, which is why they coexist on so many jobsites instead of one "perfect" saw replacing the others.

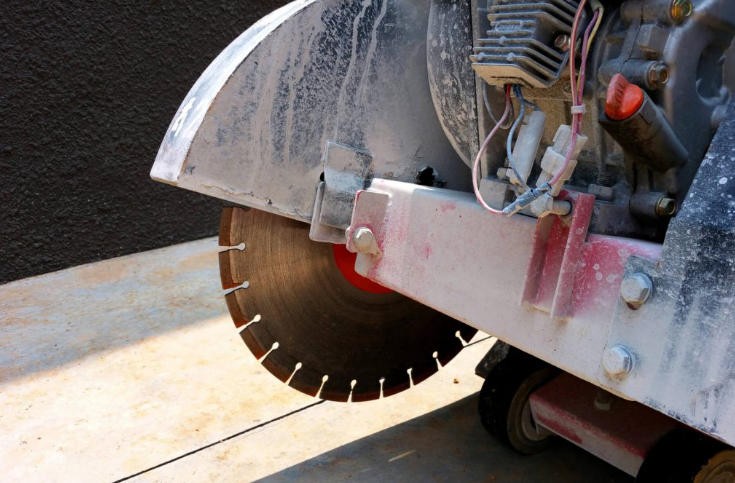

When most people picture a hand-held concrete saw, they are thinking of a center-drive cut-off saw. These include tools like petrol and electric demolition saws used on roads and construction sites.

A center-drive cut-off saw has a circular diamond blade mounted on an arbor in the middle of the disc. The motor drives this arbor directly or through a gearbox. Guards, water feeds and dust shrouds are built around the blade to manage debris and slurry. The saw is held with both hands and guided along a chalk line or marking.

Because the blade is driven from its center, only the outer portion of the disc is available for cutting. Typical examples:

•A 355 mm blade cuts to roughly 125 mm

•A 405 mm blade reaches around 150 mm

•A 457 mm blade can achieve roughly 175 mm

Beyond that, blades become large and heavy enough that hand-held operation is no longer safe, and you move into walk-behind or track-mounted wall saw territory.

Center-drive saws remain the default choice for a reason:

•Versatility – They can cut slabs, masonry, kerbs, and many other materials.

•Availability – Every rental yard and dealer stocks them in multiple sizes.

•Cost efficiency – Per metre of cut, a good cut-off saw paired with the right blade is usually the cheapest solution.

•Dry or wet cutting – Many models can run wet for dust control or dry when water is not available, provided the blade is rated for dry cutting.

If your job involves straight cuts in slabs, shortening precast pieces, or general demolition work where the depth is moderate and corners do not have to be perfectly square, a conventional cut-off saw is almost always the most economical and convenient option.

The same design that makes these saws simple and robust also introduces two major limitations:

1. Depth is tied directly to blade diameter. To cut deeper, the blade must get larger, and there is a practical limit to how large a disc can safely be on a hand-held machine.

2. Overcuts at corners. Because the blade spins around its center, completing a cut through a wall or slab will inevitably extend the kerf beyond the corner on the far side. In some applications (like decorative openings or structural details) those overcuts are unacceptable.

When you reach either of these boundaries—depth or overcut control—the next category of saw becomes very attractive.

A concrete ring saw looks at first glance like a cut-off saw with an unusually slim blade. The critical difference is how that blade is driven.

Instead of driving the disc at its center, a ring saw drives the blade around its outer edge using a friction drive or toothed system. The blade itself is a ring, not a solid disc, and the drive mechanism presses against this ring to spin it.

This has two important consequences:

•Greater depth for the same diameter. Because the drive is not in the middle, the blade can plunge past its own centerline. As a result, a 330 mm ring blade can reach around 220 mm depth, and a 405 mm ring can cut to roughly 300 mm. To get the same depth from a conventional center-drive blade would require discs in the 575–800 mm range—far beyond what you would ever use hand-held.

•More efficient use of the blade. More of the blade's circumference is actively involved in the cut, which contributes to the improved depth-to-diameter ratio.

For wall openings, deep penetrations in thick slabs, or any situation where you must cut as far as possible from one side, a ring saw can often complete the job that a standard cut-off saw cannot.

Because a ring blade can go past its center point, it can start and finish a cut in such a way that the kerf does not extend past the layout lines at the corners. In other words, you can create a rectangular opening with little or no overcut on the far side.

That makes ring saws extremely popular for:

•Door and window openings where the edge finish will remain exposed

•Structural modifications where overcuts could create stress points

•Retrofit work where adjacent finishes must remain intact

A ring saw cannot replace a wall saw in every situation, but it dramatically extends what a skilled operator can do with a hand-held tool.

Ring saws are more specialised, and that shows up in a couple of ways:

•Wet cutting only. The blade and drive system rely on water for cooling and for flushing out slurry. They are not intended for dry use.

•Slightly higher cost per metre. The consumables are more complex and typically a little more expensive per metre than those for a standard cut-off saw, though still far cheaper than a diamond chainsaw.

For many contractors, the ideal arrangement is to treat the ring saw as a "problem solver" tool. The bulk of the cutting is still done with a conventional saw; the ring saw is brought out when depth or overcuts become a problem.

Diamond chainsaws are the third major category of hand-held concrete cutting tools. At a glance, they resemble a large timber chainsaw, but the resemblance ends there: instead of sharpened teeth, the chain carries diamond segments designed to grind concrete, masonry or stone.

Diamond chainsaws exist because they can do things neither a cut-off saw nor a ring saw can do comfortably:

•Exceptional depth from one side. A chainsaw can cut as deep as the bar will allow. On thick walls or heavily reinforced elements where access is only possible from one side, that can be critical.

•Very small openings with no overcuts. Because the nose of the bar can be plunged straight into the material, you can create square or rectangular openings with sharp corners and no visible overrun.

•Curved or irregular cuts. Within limits, the operator can steer a curve, follow a radius, or cut around existing openings.

These abilities make chainsaws invaluable for applications like doorway retrofits where finishes must remain intact, pipe penetrations tucked into corners, and structural alterations in confined spaces.

The main downside of a diamond chainsaw is not usually the tool itself but the chain. Diamond chains are intricate to manufacture and wear out more quickly than blades in many applications. That means the cost per metre of cut is noticeably higher than with a cut-off saw or ring saw.

For this reason, experienced operators rarely use a chainsaw for an entire cut unless there is no alternative. A common method is pre-cutting:

1. Perform as much of the cut as possible with a conventional saw or ring saw.

2. Switch to the chainsaw only to finish corners, extend depth where necessary, or free the last remaining material.

Handled this way, a diamond chainsaw becomes a precision finishing tool rather than a high-cost primary cutter, and its strengths can be used without blowing out the consumables budget.

With three main options on the table, many contractors still find themselves asking the same question that titles this article: Which hand-held concrete saw should I choose? Instead of guessing, walk through a simple decision framework each time.

Start by describing the cut without thinking about tools at all:

•What material are you cutting—plain concrete, reinforced concrete, block, stone, or a mix?

•How deep must you go, and is that depth truly required, or just a "nice to have"?

•Can you cut from both sides? If not, what is the maximum depth from the accessible side?

•Are overcuts at corners acceptable, or must they be avoided?

•Is the work indoors or outdoors? Do you have access to water and adequate ventilation?

Once you have these answers, the right saw often becomes obvious.

In very broad terms:

•If the cut is relatively shallow, straight, and accessible from one or both sides, a center-drive cut-off saw will almost always be the fastest and cheapest choice.

•If you need significantly more depth from one side, or if overcuts at corners are a problem, a ring saw is usually the next step.

•If you are cutting very thick material from one side only, creating small openings with absolutely no overcuts, or need to follow an irregular line, a diamond chainsaw is often the only practical option.

Seen this way, the three tool types do not compete so much as they complement each other. Many contractors own or rent all three and simply move up the ladder as the demands of the cut increase.

To make this more concrete (no pun intended), consider a few common situations.

You need to cut a control joint 40 mm deep in a new slab to manage shrinkage cracking. The cut is straight, outdoors, and overcuts are not an issue. A small, light cut-off saw with a suitable blade is the obvious choice. There is no need to introduce the complexity or cost of ring or chainsaws when a standard saw can do the job quickly.

You must cut a new doorway through a 200 mm reinforced concrete wall. Only one side is accessible, and the corners will remain visible after the opening is finished.

If you tried to do this with a center-drive saw, you would find that:

•The blade cannot reach full depth from one side without becoming uncomfortably large.

•Even if you manage the depth, the corners will show overcuts.

A ring saw is a much better fit. A 330 mm ring blade can manage the required depth, and with careful technique, you can keep overcuts extremely small or eliminate them entirely. If the wall is even thicker or access is awkward, you might rough out the opening with the ring saw and then switch to a diamond chainsaw to finish the corners cleanly.

You need to make a compact rectangular opening around existing pipework in a slab, in a confined plant room where there is little room for a large saw and overcuts cannot be allowed to run under nearby equipment.

Here, a diamond chainsaw comes into its own. The bar can be plunged and steered precisely, allowing you to work around existing services and stop the cut exactly where required. Using a heavier cut-off saw in this situation would be slower, harder to control, and more likely to damage nearby assets.

Whichever type of hand-held concrete saw you choose, professional results depend on more than just owning the right tool. Technique and maintenance decide whether you get clean, accurate cuts and reasonable tool life—or constant problems and spiralling costs.

Concrete cutting generates heat and either dust or slurry. Running a saw dry without adequate breaks or airflow overheats the segments and core, glazing the diamonds and drastically shortening blade life. Using water correctly:

•Cools the blade or chain

•Reduces dust and silica exposure

•Washes debris out of the cut, improving speed

Ring saws and diamond chainsaws are designed around wet cutting and should always be supplied with sufficient water. When a cut-off saw is used dry because water is not feasible, the operator must respect duty cycles and allow the blade to cool between passes.

A common mistake with all three tool types is to push too hard. Excessive feed pressure does not make the cut proportionally faster; instead, it:

•Causes the motor to labour and overheat

•Bends or deflects the blade, leading to crooked cuts

•Increases vibration and operator fatigue

•Can strip diamond segments from the bond

The correct technique is to maintain steady, moderate pressure and let the tool's own weight and the sharpness of the diamond segments determine the rate of advance. If the cut feels slow even with good technique, it is usually a sign that the blade or chain is worn out or not matched to the material.

Finally, never underestimate the importance of using the right specification of blade or chain. Different bonds and segment designs are optimised for hard aggregate, abrasive block, asphalt, heavily reinforced concrete, and other conditions. Trying to "make do" with a blade that was designed for something else often costs more in lost time and premature wear than simply buying or renting the correct consumable.

Choosing the right hand-held concrete saw is less about chasing a particular model and more about understanding what each design can do for you. Center-drive cut-off saws are the everyday workhorses—simple, robust, and economical for the majority of straight cuts. Ring saws extend your reach when depth and corner control become critical, delivering deep, clean cuts from a blade size that is still manageable in the hands. Diamond chainsaws step in when nothing else can reach, allowing you to cut thick sections from one side, create precise openings, and work in tight or complex spaces.

If you start every decision by asking what the finished cut needs to look like—how deep, how clean at the corners, and from which side you can work—the right tool usually becomes obvious. Use cut-off saws wherever they can do the job, bring in ring saws when depth and overcuts become limiting, and reserve diamond chainsaws for the specialist tasks only they can perform. That's how you stay safe, protect your consumable budget, and deliver professional-grade concrete cutting on every project.