Views: 0 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

Ring saws are one of those tools that many people have heard of, but few really understand. On modern building sites, they are an incredibly effective option for cutting concrete and masonry, especially when you need to create openings in existing walls, floors, or slabs. Their real strength shows up in confined spaces and hard-to-reach locations where larger road saws or wall saws simply won't fit.

In this guide, we'll go beyond the basics. You'll learn how a ring saw works, what it is used for, how it compares to other concrete saws, and how to choose it for your project. By the end, you'll know when a ring saw is the right tool—and when another option may be better.

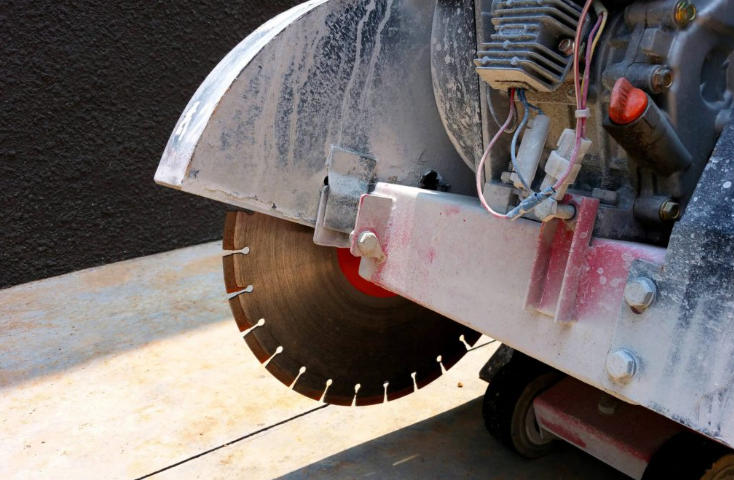

A ring saw is a handheld power saw that looks a little like a cut-off saw at first glance, but the blade design is completely different. Instead of a solid circular disc, it uses a rigid circular ring that is driven by rollers around its outer edge. The cutting surface is usually a diamond-coated abrasive rim, not traditional teeth.

Because the drive system does not rely on a central arbor, the entire ring is free to cut. This design gives the tool much greater cutting depth than a standard disc saw of the same diameter. Depending on the model and blade size, many concrete ring saws can cut up to 270–430 mm deep in one pass—far deeper than a typical 350–400 mm cut-off saw blade.

Professional users often pair ring saws with high-frequency electric machines such as the diamond ring saw machine D390, which combines a brushless motor with wet cutting to handle demanding wall and floor cuts.

Most construction ring saws are:

•Handheld and relatively compact

•Powered by electric, hydraulic, or high-frequency motors

•Designed for wet cutting, with integrated water feed to cool the blade and control dust

Because ring saws are portable but still offer deep cutting, they fill a very specific niche on construction and renovation projects. They are ideal when:

•The area cannot be reached by a road saw or wall saw,

•But you still need deeper cuts than a standard hand saw can provide.

Typical applications include:

•Creating openings in reinforced concrete or brick walls for:

Windows

Doorways

Ventilation grilles

Duct or pipe penetrations

•Cutting concrete pipes and manholes in situ

•Deep cuts in concrete floors and slabs, especially near columns or obstructions

•Precision work where you want to minimise over-cutting at the corners

A ring saw can cut through almost any hard construction material when paired with the right diamond ring blade, including:

•Reinforced and plain concrete

•Masonry and brick

•Natural stone such as granite, sandstone, and marble

•Precast elements and concrete blocks

Specialty blades can also be used for hard materials like glass or thick acrylic in architectural or artistic applications, although this is less common on typical building sites.

Many contractors wonder when to choose a ring saw instead of a cut-off saw, chain saw, or wall saw. The table below summarises the main differences conceptually:

•Cut-off saw (disc saw): Good for shallow to medium cuts (typically up to around 125–150 mm), fast for straight cuts in accessible areas.

•Concrete chain saw: Excellent for square corners and irregular shapes; depth depends on bar length but can be high; chain wear and maintenance are significant.

•Wall saw: Track-mounted, extremely precise, ideal for large openings and very thick structures, but requires setup space and access.

•Ring saw: Handheld like a cut-off saw, but with much deeper cutting capacity and minimal over-cut at corners. Perfect for tight, awkward positions where a wall saw cannot be set up.

If you need:

•Deep cuts in confined spaces,

•Square corners with little or no over-cut,

•Or clean openings in existing walls without removing a lot of extra material,

then a ring saw is often the most efficient and controlled choice. For large structural openings or elevator shafts, something like the ring saw machine for cutting wall or High Power Electric Ring Saw Concrete Cutting Machine gives you even more cutting capacity while staying portable.

The original article listed four main advantages. Let's keep those points and expand them so they are more useful for real-world decision-making.

Ring saws are both portable and extremely capable. A typical concrete ring saw can achieve cutting depths around 270 mm (and some specialist models up to 430 mm), allowing you to penetrate many standard structural walls and slabs from one side.

What this means on site:

•You can create full-depth openings in many walls without needing to cut from both sides.

•The tool is light enough to be carried onto scaffolding, into basements, or up staircases, unlike larger track-mounted systems.

•The ring blade design allows for tight inside corners and right-angle cuts, so you can open window or door penetrations with less patching and cosmetic repair afterwards.

In short, a ring saw gives you cut depth approaching that of bigger systems in a package that still behaves like a handheld saw.

Most ring saws are designed to run with a continuous water supply. The water cools the diamond segment, increases blade life, and—critically—captures a large portion of the dust at the source. Wet cutting produces a slurry rather than airborne silica dust, which helps you work closer to regulatory dust control standards and keeps the working environment more comfortable.

From a practical standpoint:

•Operators breathe in less fine dust, which is better for long-term health.

•Visibility around the cut is often improved compared to dry cutting with heavy airborne dust.

•The slurry does need to be contained and cleaned up, but this is usually easier to manage than uncontrolled dust in finished interiors.

If you frequently work indoors or in dust-sensitive environments, pairing a wet ring saw with the right concrete saw blades helps strike a good balance between productivity, blade life, and safety.

The original article notes that ring saw blades are abrasive rather than toothed, and that skin is soft so it can "bounce harmlessly off the bumps." In reality, a ring saw is still a serious, high-energy cutting tool that can cause severe injury if misused. However, compared with aggressive toothed blades, the diamond abrasive rim tends to grab less and offers smoother engagement with the material.

Key safety advantages when operated correctly:

•Reduced risk of violent kickback compared to some toothed blades.

•The blade is designed to grind through very hard materials; soft materials like skin do not "feed" into the blade in the same way teeth would.

•Because cuts are precise and controlled, there is less chance of over-cutting into hidden pipes or reinforcement, especially when layouts are carefully marked and checked in advance.

Nevertheless, operators must always wear full PPE (eye, ear, respiratory, and hand protection), follow manufacturer guidelines, and verify there are no live services behind the cut line.

A ring saw operates by spinning a continuous ring blade on powered rollers. Instead of each individual tooth striking the material like a hammer, the diamond segments grind through the concrete with a more constant contact. This typically results in lower perceived vibration for the operator and less chipping or spalling on delicate surfaces or finishes.

Benefits of reduced vibration include:

•Better comfort and reduced fatigue during longer cuts

•More precise control near edges, corners, and existing finishes

•Less stress on the machine's internal components and bearings, potentially extending tool life

It's more accurate to say ring saws offer low-vibration cutting rather than "no vibration," but the difference compared with some alternative cutting methods is very noticeable in practice.

To turn these technical details into a clear decision, consider the following questions for your project:

1. How thick is the concrete or masonry?

•Up to ~100–125 mm and easily accessible: a standard cut-off saw may be enough.

•150–300 mm, especially in reinforced walls: a ring saw provides the depth you need without major demolition.

2. Is the work area confined or awkward to reach?

•Tight basements, stairwells, elevator shafts, or areas behind pipework are classic ring saw territory, where wall saws and road saws cannot be positioned.

3. Do you need clean, square openings with minimal over-cut?

•For windows, doors, and vents where the visual finish matters, the ability of a ring saw to start and stop cuts right in the corner can significantly reduce patching and

•make later framing or fitting easier.

4. What are the dust and noise limitations on site?

•Indoor renovation projects, hospitals, or live commercial spaces often have strict dust limits. A water-fed ring saw helps control airborne dust, though you will need a plan to manage slurry.

If you answer "yes" to most of these scenarios—deep cuts, tight space, clean openings, dust-sensitive environment—a ring saw is usually the most efficient and professional choice. For drilling-type penetrations instead of long cuts, a dedicated tool such as the hand held diamond core drill machine may be a better match.

A detailed operating manual will vary by brand, but most workflows follow this general pattern:

1. Survey and mark the work area

•Confirm the structural design and check drawings for hidden services, rebar, and post-tension cables.

•Use scanners or detection tools where possible to avoid "cutting into something you shouldn't" such as live electrical conduits or plumbing.

2. Plan drainage and protection

•Because the saw runs wet, set up water containment, drainage, and splash protection for nearby finishes or equipment.

3. Set up the saw and blade

•Fit the appropriate diamond ring blade for the material.

•Check blade condition, guard alignment, and roller drive components.

•Connect the water supply and test the flow.

4. Make a test cut

•Start in a non-critical area to check blade tracking, water delivery, and machine behaviour.

5. Perform the main cut

•Follow your marked lines steadily without forcing the blade.

•Let the abrasive edge do the work; too much pressure can overheat the segment and reduce life.

•For thick walls, consider cutting in passes rather than trying to force full depth in one go.

6. Finish corners and edges

•Use the ring saw's ability to cut right into corners to square up openings.

•If necessary, tidy up edges with additional shallow passes.

7. Clean up slurry and inspect the work

•Remove water and slurry, check for over-cuts or exposed reinforcement, and verify the opening dimensions before installing frames or services.

•How deep can a concrete ring saw cut?

Depending on the model and blade diameter, ring saws typically cut up to 270–430 mm deep, giving roughly twice the cutting depth of many standard 350–400 mm disc blades.

•Can a ring saw cut reinforced concrete?

Yes. With the correct diamond ring blade, these tools are designed for reinforced concrete and masonry, including walls, slabs, and structural elements. Blade choice and operator experience are critical for efficient cutting through heavy rebar.

•Is a ring saw better than a concrete chain saw?

It depends on the job. Chain saws excel in irregular shapes and extremely deep cuts, while ring saws often provide smoother, cleaner cuts with less maintenance and lower running costs for typical door and window openings. On many projects, contractors use both tools together.

•Do I always need water with a ring saw?

Most construction ring saws are designed for wet cutting. Water dramatically reduces dust and heat and is strongly recommended for concrete and masonry. Some specialised models and blades may allow limited dry cutting, but always follow the manufacturer's instructions.