Views: 0 Author: Anna Publish Time: 2025-10-10 Origin: Site

In the fast-evolving field of precision machining, efficiency and reliability are no longer optional—they are essential. Traditional tools often struggle when cutting through hard and abrasive materials such as ceramics, stone, and high-strength alloys. This is where vacuum brazing technology plays a transformative role. By permanently bonding diamond particles to the tool surface through a high-temperature vacuum process, brazed tools combine durability, precision, and versatility. From stone fabrication workshops to mold manufacturing plants, these tools have become indispensable in meeting the demands of modern industries.

Vacuum brazing is a controlled process where diamond grits are attached to a steel or alloy substrate using a metallic filler, typically nickel-chromium-based alloys. Conducted inside a vacuum furnace, the process ensures minimal oxidation and prevents diamond graphitization, which could otherwise weaken the tool. Unlike electroplated tools, which tend to lose grit prematurely, brazed tools expose a larger portion of the diamond surface, delivering higher cutting efficiency and longer tool life. Compared to sintered tools, which embed diamond within a matrix, brazed tools provide sharper edges and faster material removal—qualities particularly valuable in high-precision applications.

Among the most widely recognized brazed tools is the vacuum brazed diamond finger bit. Designed for shaping and milling, this tool excels in delicate detailing where precision is paramount. In mold manufacturing, it allows technicians to carve intricate profiles without compromising accuracy. In stone carving, it empowers artisans to create fine cuts with smooth edges. The exposed diamond grit ensures rapid cutting action while resisting premature wear. As a result, users can achieve complex geometries efficiently, reducing both time and cost in high-value production processes.

Edge finishing is another critical area where brazed tools stand out. The vacuum brazed diamond chamfer bit, also known as a countersink drill bit, is engineered to deliver smooth, precise bevels on materials such as stone, ceramic, and metal. Its design allows for stable cutting depth, ensuring consistent chamfering results without surface damage. In architectural stonework, this reliability translates into clean and professional finishes. In metal fabrication, it ensures that parts meet strict tolerance requirements while also enhancing their appearance. Thanks to vacuum brazing, the tool withstands heavy-duty use while maintaining sharpness across multiple applications.

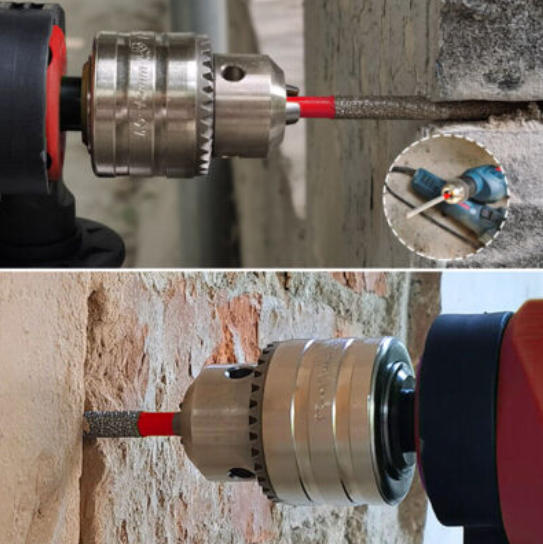

Drilling through dense and abrasive materials presents one of the toughest challenges in machining. The vacuum brazed diamond core drill bit set addresses this need with multiple sizes tailored to diverse drilling requirements. Ideal for dry drilling, these bits deliver stable performance even without coolant. In the construction industry, they are used for creating clean holes in tiles, ceramics, and reinforced concrete. In geological exploration, they provide efficient core sampling while preserving structural integrity. By leveraging brazed diamond technology, this tool set enhances drilling speed, extends service life, and ensures precision in critical applications.

The widespread adoption of vacuum brazed tools is not accidental. Their advantages are rooted in material science and process engineering. The strong adhesion between diamond grit and substrate reduces the risk of particle loss, allowing tools to maintain performance under high-stress conditions. The high diamond exposure rate ensures faster cutting and cleaner surfaces, minimizing the need for post-processing. Additionally, these tools are versatile across industries, finding applications in construction, stone fabrication, metalworking, and mold making. While they may not always match the extreme longevity of sintered tools in cutting ultra-hard granite, their combination of speed, precision, and reliability makes them a top choice for professionals.

Vacuum brazed diamond tools are redefining standards across multiple fields. In stone fabrication, they support cutting, carving, and chamfering natural and engineered stone with minimal chipping. In construction, they provide contractors with reliable solutions for drilling and edge finishing during tile and concrete work. In metalworking, they are indispensable for trimming and beveling tough alloys with precision. In mold manufacturing, their ability to maintain intricate shapes helps reduce production errors. Even in geological exploration, they deliver efficient and accurate drilling performance, supporting critical research and development projects.

The brazing process represents more than just a method of attaching diamonds to a tool—it is a technological advantage that underpins modern machining. With tools like the Vacuum Brazed Diamond Finger Bit, the Diamond Chamfer Bit, and the Vacuum Brazed Diamond Core Drill Bit Set, industries can achieve higher precision, improved productivity, and reduced operational costs. For businesses focused on quality and efficiency, adopting brazed diamond tools is not just an upgrade, but a strategic decision for long-term success.

•What makes vacuum brazed tools different from electroplated ones?

Brazed tools offer stronger adhesion and expose more diamond particles, resulting in faster cutting and longer tool life.

•Can brazed diamond tools be used dry?

Yes, many brazed tools, especially core drill bits, are suitable for dry drilling, although water cooling can extend life and reduce dust.

•Which industries benefit the most from these tools?

Key sectors include stone fabrication, construction, metalworking, mold manufacturing, and geological exploration.

•Are vacuum brazed tools cost-effective?

Although initial costs may be higher than electroplated tools, their longer lifespan and faster performance often reduce overall expenses.

•Do they replace sintered tools completely?

Not entirely—sintered tools are still preferred for cutting extremely hard materials like granite, but brazed tools excel in versatility and precision tasks