Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

• Trying to install a bathroom shelf, but your drill bit keeps slipping on the tile and smoking against the concrete wall? It's probably not your technique—it's the wrong type of drill bit.

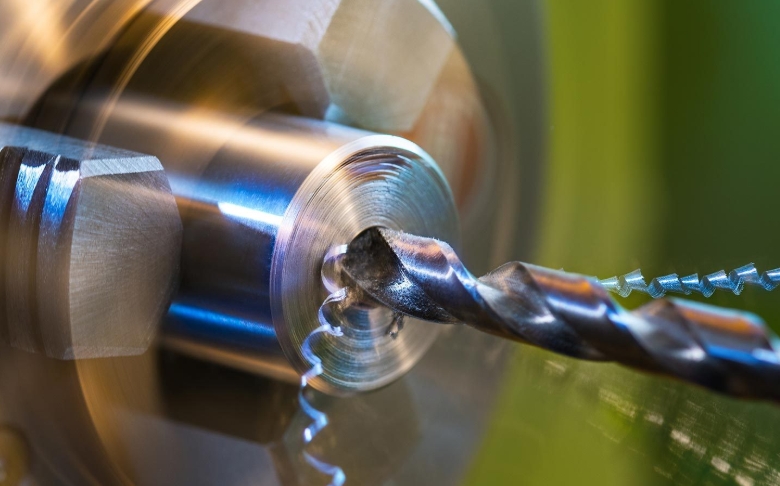

• Drilling into that shiny new stainless steel sink, but the bit turns red-hot, dulls instantly, and the hole's still unfinished? The culprit might be your drill bit selection.

When your drill bit doesn't match the job, you risk more than frustration—you compromise speed, accuracy, tool life, and safety. That's why knowing the difference between SDS and HSS drill bits isn't just a technical detail—it's the key to getting the job done right.

In this guide, we'll break down how these two drill bit types work, what they're designed for, and how to choose the right one based on your project needs.

The difference between HSS and SDS drill bits has nothing to do with shape, size, or application—and everything to do with what they're describing.

HSS stands for High-Speed Steel, a strong and heat-resistant alloy used to manufacture a wide range of drill bits.

Unlike SDS, HSS refers to the material, not the shank. HSS drill bits come in several shank styles—straight, tapered, Morse taper, etc.—and are designed for rotational drilling in materials like metal, plastic, and wood.

They are compatible with standard 3-jaw chucks and are the go-to choice for general-purpose, non-impact drilling.

SDS stands for Slotted Drive System, or in its original German, Steck-Dreh-Sitz (Insert – Twist – Stay). SDS doesn't refer to the tip material or drilling method—it describes the shank design, or how the drill bit is held in the drill.

An SDS drill bit is designed to fit into an SDS chuck system, which uses slots in the shank to hold the bit firmly without manual tightening. This system enables fast bit changes, excellent retention under heavy load, and high durability in drilling hard materials like concrete and masonry.

Many SDS bits come with carbide-tipped heads, making them extremely tough and wear-resistant—ideal for precision rotary drilling in reinforced concrete, not necessarily for impact-driven hammering.

SDS is not a material or a cutting edge — it's the connection system that holds the bit in place securely during high-load applications.

| Feature | HSS Drill Bits | SDS Drill Bits |

|---|---|---|

| Term Refers To | Bit material (high-speed steel) | Bit retention system (shank design) |

| Shank Type | Straight, reduced, or tapered shanks | Slotted or spline shanks |

| Chuck Compatibility | Standard 3-jaw chucks | SDS-specific chuck systems |

| Common Tip | Steel alloy (may include cobalt, oxide, etc.) | Carbide or diamond-coated for masonry |

| Best Suited For | Metal, wood, plastic | Concrete, masonry, heavy-duty mineral drilling |

| Installation | Requires manual tightening | Quick-insert, no tightening needed |

| Movement Type | Rotary only | Rotary only or rotary + hammer (depends on drill) |

Note: Whether a bit moves in rotation only or with a hammering effect depends on the drill mode, not the bit. SDS bits can perform either, depending on whether you're using a rotary drill or hammer drill.

HSS bits come in a variety of shapes and coatings to suit different jobs:

• Straight Shank – Fits most general-purpose drills.

• Reduced Shank – Allows larger bit diameter to fit in standard chucks.

• Tapered / Morse Taper – Used in industrial machinery and lathes.

• M35 Cobalt HSS – Contains 5% cobalt for added heat resistance and hardness.

• Black Oxide Coating – Improves chip flow and heat dissipation.

• Titanium or Gold Coating – Reduces friction and extends bit life.

HSS bits are perfect for non-impact tasks like sheet metal drilling, cabinet making, or plastic machining.

SDS bits vary by shank size and compatibility. The most common types include:

• SDS (Standard) – The original design with basic slotted shanks.

• SDS-Plus – Most widely used, 10mm shank with four slots for better grip.

• SDS-Max – 18mm shank with five slots, used for larger, more demanding holes.

• Spline – Uses a 19mm shank with spline grooves for tight torque fit in heavy-duty applications.

All of these share the same slot-driven engagement system, which minimizes slippage and enables powerful, stable cutting—even in reinforced concrete.

• You're working on metal, wood, aluminum, or plastic

• Your drill uses a standard 3-jaw chuck

• You need to make clean, accurate holes with little heat buildup

• The job involves general-purpose, non-impact drilling

HSS bits are versatile and affordable—ideal for everyday use in DIY, metal fabrication, or woodworking.

• You're working with reinforced concrete, brick, stone, or cement board

• You need maximum bit retention and longer life under high load

• You're using a drill with SDS chuck compatibility

• You require precision rotary drilling in tough materials (especially with diamond-tipped SDS bits)

SDS bits, especially those with carbide or diamond heads, are built to drill hard surfaces like concrete with minimal wear and reduced vibration.

More read: SDS Core Bit - Efficiency Revolutionizers for Construction Contractors

Using the wrong bit can lead to:

• Poor hole quality

• Tool damage

• Wasted time

• Overheating and early wear

Understanding that SDS is a shank system and HSS is a material type helps you choose smarter. It's not about which one is better overall—it's about choosing the right one for the job.

No. SDS bits require a special SDS chuck system and won't fit into standard 3-jaw chucks.

Not at all. HSS bits are not designed to withstand the abrasive aggregate and load stress of concrete. You'll experience:

• Fast edge wear and tip dulling

• Overheating and softening of the steel

• High risk of jamming or breakage

• Poor drilling speed and efficiency

Instead, use SDS carbide-tipped or diamond-coated bits specifically made for masonry and concrete.

SDS-Plus has a 10mm diameter and four slots, offering better retention. It's compatible with most light rotary hammers and is the most common SDS type today.

Yes—for harder metals like stainless steel or cast iron, cobalt bits offer higher heat tolerance and wear resistance. But for soft materials like wood or mild steel, standard HSS is often more cost-effective.

No. Their shank shapes, drill compatibility, and application focus are entirely different.

Next time you reach for your drill, ask: "Am I cutting into concrete—or shaping precise holes in metal or wood?"

• SDS Drill Bits = The heavy-duty pro for hard, abrasive materials like concrete

• HSS Drill Bits = The flexible workhorse for metal, plastic, and wood

Match your bit to the job—and you'll save time, protect your tools, and get a better finish. Still unsure? Recommended Senmine SDS drill bits for you:

| Product Name | SDS Drill Bits |

| Outer Diameter | 32–120 mm |

| Finish | Spray Painting |

| Usage | Construction Hole Cutter |

| Material | Metal Bond with Diamond Segment |

| Advantage | Operator Safety, Fast Drilling |

| Application | Concrete, Hard Concrete, Reinforced Concrete |