Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

If you work with granite long enough, the same questions keep coming back: Why is this brand-new granite saw blade chipping my countertop? Why did the last blade burn out halfway through the job? Can I really use the same blade for granite, marble and concrete? Most of these headaches don't come from "bad blades", but from mismatched choices: the wrong blade type for the material, the wrong diameter for the saw, or the wrong bond and RPM for the job.

This buying guide is written for fabricators, installers, and contractors who need clean, predictable cuts on granite without burning through blades or blowing up the budget. Instead of listing random specs, it explains how granite behaves, what makes a true granite saw blade different, how to match blade types to machines and jobs, and how to balance cutting speed against blade life. By the end, you should be able to look at a project, look at your saw, and decide quickly which granite saw blade makes sense – and when it's smarter to talk directly with a SENMINE manufacturer for a custom or OEM solution instead of guessing at the local store.

Granite is one of the most demanding stones from a blade's point of view. It is packed with quartz and feldspar crystals, so the surface is extremely hard. At the same time, the grain structure is uneven and the edge of a slab is surprisingly brittle, especially along a polished front edge or around a sink cutout. That mix of hardness and brittleness is why a generic masonry blade may "cut" granite but leaves chipped edges, burn marks, or extremely slow progress.

A real granite saw blade is built with a bond and diamond mix tuned specifically for this kind of stone. The metal bond has to be soft enough to release worn diamonds so fresh ones can keep biting into the quartz, but strong enough to resist the abrasive fines in the slurry. Segment shape and rim design also help control chips along the top surface. Once you understand that granite is not just "another rock", it becomes obvious why using a random concrete or tile blade leads to poor cut quality and short blade life.

Many users start with whatever blade is already on the saw: a concrete blade from a previous job, a cheap tile blade, or a general-purpose diamond blade from a hardware store. On granite, these usually fail in the same way. The blade either glazes over and stops cutting, overheats and turns blue, or tears out big chips where you most want a clean line. A concrete blade's bond is often too hard for dense granite, so the diamonds dull without being released. A basic tile blade might be fine on soft ceramic, but struggles to stay sharp on harder stone.

It might be possible to get through a few cuts, but the cost per meter becomes high in rework, polishing time, and accelerated wear. If your work regularly involves granite, it deserves its own dedicated blade category. Granite-specific blades cut faster, run cooler, and hold a more consistent line, which directly protects both the material and your profit margin.

Segmented granite saw blades have visible gullets separating each diamond segment. These gaps clear slurry and help the core run cooler, which makes segmented blades a popular choice for fast, aggressive cutting. On outdoor jobs, granite pavers, and rough shaping work, a segmented diamond blade for granite can remove material quickly and survive tougher conditions. The trade-off is edge quality: you usually see more micro-chips along the cut line, especially on polished surfaces or thin pieces.

If your priority is square meters per day, not mirror-finish edges, segmented granite blades are often the pragmatic option. They work well with more powerful saws and wet cutting, where plenty of water keeps heat under control. For contractors dealing with both granite and rough site materials, a robust segmented granite blade offers the durability and speed needed to stay on schedule, even in less-than-ideal conditions.

Turbo granite blades sit between segmented and continuous rim designs. They use a solid rim with serrations or "turbo" slots that increase surface area and help clear slurry, giving a good balance of cooling and cutting pressure. In practice, turbo diamond blades for granite often become the default choice for installers who cut both on site and in small workshops. They cut faster than most continuous rim blades, yet with better chip control than many coarse segmented designs.

On a granite kitchen countertop, a turbo blade can handle straight cuts, rough sink openings, and field trimming of edges with reasonable cleanliness. When combined with wet cutting, the serrated rim helps keep the blade cool for multiple passes without excessive blueing of the core. For many users, a high-quality turbo granite blade becomes the "one blade that does almost everything" in daily work.

When top surface appearance matters more than raw speed, continuous rim granite blades are the first choice. They use a smooth, uninterrupted diamond rim that distributes cutting forces evenly around the edge, which dramatically reduces chipping and micro-fractures on polished granite. Because there are no large gullets, these blades rely heavily on water flow for cooling and slurry removal and are typically used for wet cutting on tile saws or bridge saws rather than dry on an angle grinder.

For sink cutouts, exposed front edges, decorative inlays, and other high-value finishes, a continuous rim diamond blade for granite gives the best chance of a clean, ready-to-polish surface. Cutting speed is slower than an aggressive segmented blade, but time saved on edge repair can easily offset this in a production environment. Combined with appropriate diamond polishing pads, a quality continuous rim granite blade forms the foundation of a premium edge-finishing system.

More read: Segmented Blade vs Turbo Blade vs Continuous Rim Blade

Angle grinders are the most common tool people grab for cutting granite on site. They are compact, relatively powerful, and can handle small-diameter granite saw blades from about 4.5" to 7". With the right turbo or segmented blade, an angle grinder can open faucet holes, trim edges, or create makeshift cuts in slabs that are already installed. The downside is control: because the grinder is handheld and spins at high RPM, any wrong movement shows up as a scratch, chip, or uneven line on the stone.

When choosing a granite blade for an angle grinder, check the arbor size (commonly 22.23 mm or 7/8") and make sure the maximum RPM printed on the blade is higher than the grinder's no-load speed. For delicate cuts near finished surfaces, use a finer, continuous or fine-turbo rim and shallow passes, ideally with dust control and, where safe, water cooling. For deeper or structural cuts that exceed what small blades can reach, larger saws or ring saw systems are often a safer and more efficient choice.

Circular saws and track saws are useful for making straight, controlled cuts in granite tiles or thin slabs, especially in jobsite conditions where a full bridge saw is not available. With a proper granite saw blade in 7 1/4" or 9" size, a circular saw can cut countertops, windowsills, and stair treads to length. The key is setup: the slab must be fully supported, the blade depth correctly set just below the material thickness, and the saw guided along a straight track to avoid wandering cuts and chip-out.

When buying a granite blade for a circular or track saw, match the blade diameter, arbor bore, and kerf width to the saw's spec sheet. Look for blades clearly rated for granite, not just "masonry" or "tile". For long cuts on polished surfaces, a turbo or continuous rim wet blade generally gives cleaner edges than a coarse segmented design. Good support, clean guides, and a steady feed are just as important as blade selection for straight, chip-controlled cuts.

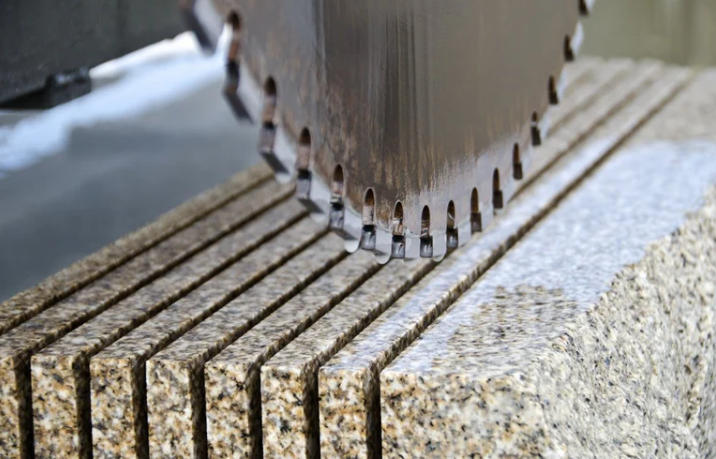

Granite shops and higher-volume contractors typically rely on tile saws and bridge saws for most of their cutting. These machines run larger diameter granite saw blades – 10", 12", 14", 16" or even 18" – with adjustable feed rates and built-in water supply. Here, the blade is part of a production system: it needs to cut straight, cool, and predictably day after day. Choosing the wrong blade can mean constant dressing, chipping, and inconsistent edges that slow polishing and increase rework.

For bridge saws, continuous rim or fine-turbo granite blades are often used on visible edges, while more aggressive segmented blades handle block trimming or thicker stock. Always check maximum RPM and ensure the saw's speed control is set within the recommended range printed on the blade. Matching blade diameter, core quality, segment design, and machine power is essential for reliable, repeatable performance in a stone shop.

For most high-value granite work, wet cutting is not just a recommendation – it is essential. Water cools the granite saw blade, flushes out abrasive slurry, and dramatically reduces micro-chipping along the top edge. If you are cutting polished countertops, sink openings, or any visible edges, a wet-use granite blade and a saw that can safely deliver water to the cut are the standard approach. Without water, heat builds up at the diamond segment, softening the bond, glazing the rim, and eventually warping or cracking the core.

Wet cutting also helps control dust, especially respirable silica, which is a significant health risk in granite shops and on job sites. A proper wet granite saw blade used with adequate water flow gives cleaner cuts, longer blade life, and a safer working environment. For any regular granite fabrication or installation work, a wet-capable saw and dedicated wet granite blades should be treated as core investments rather than optional upgrades.

There are still situations where dry cutting granite makes sense, especially on small jobs or in places where bringing water is impractical. Short cuts in granite pavers, notched pieces for outdoor steps, or quick on-site adjustments can often be done with a dry-rated turbo or segmented granite blade on an angle grinder or handheld saw. The important thing is to treat "dry" as a limitation. Light passes, cooling pauses, and attention to heat and sparks are essential.

When buying a granite saw blade for dry use, look specifically for "dry/wet" or "dry cut" ratings and a vented or turbo rim design that helps move air through the cut. Avoid using a "wet only" continuous rim blade for long dry cuts; it will overheat and can become dangerous. A simple rule of thumb is: wet blades and wet cutting for finish edges and longer cuts, dry-capable blades for small, controlled jobs where speed and convenience matter more than perfect surfaces.

Beyond cut quality and blade life, health and safety should always be part of blade selection. Granite dust contains crystalline silica, and uncontrolled dry cutting can quickly push airborne levels beyond safe limits. Even when wet cutting reduces visible dust, proper respiratory protection, eye protection, hearing protection, and housekeeping are crucial in both workshops and job sites.

Overheating is another hidden risk. A granite blade that routinely runs too hot can suffer micro-cracks in the core and segment brazes, increasing the chance of segment loss or catastrophic failure. If you notice blades turning blue, throwing excessive sparks, or giving off a burning smell, that is a red flag. Correct blade selection, adequate water supply, appropriate feed speed, and adherence to RPM limits all contribute to safer, more stable cutting.

Read more: Wet vs Dry Cutting: Does A Wet Blade Cut Better?

The first specs most buyers see on a granite saw blade are the diameter and arbor size. These must match the saw's guard capacity and spindle bore. A 115 mm (4.5") or 125 mm (5") blade suits most angle grinders, while 180–230 mm blades fit larger hand saws. Bridge saws often run 300–450 mm blades and beyond. Diameter determines not only what fits under the guard but also the maximum cutting depth: roughly one-third to one-half of the blade's diameter in real-world setups, depending on guard design and flange positioning.

Think backward from the material and cut depth you need. For 20–30 mm countertops, a 4.5" or 5" blade is adequate for trimming; for thicker steps or pavers, 9–14" may be required. Always confirm the arbor size – for example, 22.23 mm, 20 mm, or 1" – and avoid low-quality adapters. A clear understanding of diameter, bore, and cutting depth ensures that your chosen granite saw blade will work safely and effectively with your specific machine.

Segment height is a useful indicator of potential blade life, although it is not the only factor. A granite saw blade with 10–12 mm segments contains more usable bond and diamond than one with 7 mm segments. For heavy users, such as stone fabrication shops or large construction projects, taller segments can lower the cost per meter of cut because you spend less time changing blades and more time cutting. However, tall segments also need to be matched with the right bond hardness and machine power; otherwise, they may not wear evenly and can glaze or crack prematurely.

A worn-looking steel core with plenty of segment left is often a sign of improper dressing or overheating, not just normal wear. When comparing blades, look at segment height together with other quality indicators such as core flatness, brazing quality, and consistency of the segment finish. A well-designed granite blade with moderate segment height, correct bond, and appropriate dressing practices can outperform a taller but poorly engineered alternative.

Bond hardness and diamond grit size are less visible on a spec sheet, but they make a huge difference in how a granite saw blade behaves. A softer metal bond allows dull diamonds to pull out and exposes fresh ones, which is ideal for very hard, low-abrasion materials like dense granite. A bond that is too hard will hold onto worn diamonds, causing glazing and a sudden drop in cutting speed. Conversely, a bond that is too soft in very abrasive conditions can wear away too quickly, sacrificing life for speed.

Grit size shapes the trade-off between speed and finish. Coarser grit cuts faster but leaves a rougher kerf with more micro-chips; finer grit produces smoother edges at lower feed rates. For general granite work, many professional blades are tuned to a medium-fine range that balances productivity with acceptable surface quality. Dedicated granite blades from manufacturers like SENMINE are engineered around these variables to deliver consistent performance across different granite types, which is a clear advantage over generic "masonry" blades.

Every granite saw blade comes with a maximum safe RPM, but there is also an optimal working range where the diamonds cut efficiently without overheating. Running too fast can increase heat and wear, while running too slow may cause the blade to rub instead of cut. When blades and machines are mixed without checking RPM compatibility, performance suffers and blade life shortens. Always compare the saw's no-load RPM and blade diameter to the values printed on the blade's label and technical sheet.

Saw power also matters. Underpowered machines struggle to maintain speed when entering hard granite, especially with large-diameter blades. This causes stalling, vibration, and uneven wear on the segments. For reliable performance, blade diameter, bond design, saw power, and feed speed must all work together. A properly tuned system will always outperform a random mix of tools, even if the individual components look similar at first glance.

Granite kitchen countertops are where blade selection is most visible. A chipped front edge or rough sink opening will either cost time in polishing or disappoint the end customer. For straight cuts on slabs before installation, a continuous rim or fine-turbo granite blade on a wet bridge saw gives a smooth, precise result. For sink and cooktop cutouts, many shops use a combination approach: roughing out corners with a turbo blade on an angle grinder, then refining edges with a continuous rim blade and polishing tools.

Blade choice should follow the task. A 14" continuous rim granite blade works well for long countertop rips on a bridge saw, while a 5" turbo blade suits on-site trimming, notches, and transitions around cutouts. Pairing the cutting step with appropriate diamond polishing pads reduces the time and effort required to reach a high-gloss finish. Clean cuts, minimal chipping, and manageable polishing steps are the signs that the blade is well matched to the countertop work.

Outdoor projects such as granite pavers, steps, kerbs, and landscaping blocks have very different priorities. Edges are often hidden or later chamfered, so perfect polish is less important than productivity and robustness. In these situations, segmented or coarse-turbo granite blades are particularly effective. They tolerate dustier environments, less consistent water supply, and the occasional mixed cut through bedding mortar or backing material.

For landscaping, the goal is to move quickly, keep the saw cool enough, and avoid premature segment loss. A durable segmented granite blade on a handheld saw or floor saw can cut through thick pavers and steps with enough speed to keep the project on schedule. Slightly rough edges can typically be hidden or dressed with simple finishing tools, so a blade that favors speed and toughness over mirror finishes is often the best investment.

Even when the main cut is complete, blade choice still matters for edge profiling. Some fabricators prefer to rough-shape edges with a turbo granite blade on a variable-speed grinder before switching to profiling wheels and polishing pads. Others rely on bridge saws with miter cuts and then refine by hand. In both cases, starting with a blade that leaves a smoother surface reduces the number of polishing steps needed to reach a high gloss.

A finer-grit continuous rim blade is often the best starting point for visible edges, especially on darker granites where micro-chips are very noticeable. A clean, straight cut provides a consistent base for subsequent profiling and polishing. When the cutting stage is handled properly, the finishing stage becomes faster, more predictable, and less dependent on aggressive correction of defects left by an unsuitable blade.

At first glance, a cheap "universal" diamond blade and a branded granite saw blade can look similar: both have segments, both claim to cut stone, and both fit the same saw. The real difference shows up after a few meters of granite. Low-cost blades often use inconsistent diamond quality, poorly controlled bond hardness, and less precise segment attachment. On hard granite, they glaze rapidly, overheat, and may lose segments when pushed beyond light DIY use.

A blade that costs half as much but lasts one-third as long and cuts slower with more rework is not actually cheaper. When you factor in labor, polishing, scrap, and downtime, the apparent saving disappears. A dedicated granite saw blade with stable performance and predictable wear gives better control over both cost and quality. For professionals, this stability is often more important than the initial price on the invoice.

Premium granite saw blades become cost-effective when viewed through the lens of productivity and predictability. A blade that consistently delivers clean cuts at a known feed rate makes scheduling easier and reduces the risk of surprise failures midway through a job. For a stone fabrication shop or a contractor installing multiple countertops a week, that reliability converts directly into fewer call-backs, less overtime, and smoother coordination with other trades.

A well-engineered granite blade also allows operators to trust the tool. When they know how it will behave on each pass, they work faster and more confidently. Over time, the reduction in rework, scrap, and downtime more than offsets the higher purchase price. This is where blades from specialized manufacturers like SENMINE demonstrate their value: they are designed to perform as predictable production tools, not just as occasional-use consumables.

When you move beyond retail brands and start dealing directly with a granite saw blade manufacturer, the conversation can be tailored to your real-world conditions. Instead of just choosing a diameter and segment height from a catalog, you can share information about your material mix, saw models, target cutting speeds, and quality expectations. A capable manufacturer like SENMINE can then recommend bond hardness, segment shapes, and core designs that match your situation.

Useful questions to ask include: Do they test blades on real granite rather than only on lab blocks? Can they provide references from similar shops or projects? Do they offer OEM or private-label options if you want to build your own blade brand? Are they transparent about batch consistency and quality control? Working with a manufacturer as a technical partner rather than just a supplier helps ensure that your granite saw blades fit your workflow instead of forcing your workflow to adapt to generic tools.

Before you place an order, run through a simple checklist to avoid common mistakes:

• What type of granite are you cutting (densely crystalline, highly veined, or mixed)?

• What thickness and size are the slabs or pavers?

• Which saw will you use (angle grinder, circular saw, tile saw, bridge saw, ring saw)?

• Do you have reliable water supply for wet cutting, or must you cut dry in some cases?

• Is edge appearance critical (kitchen countertops) or acceptable to be rough (landscaping)?

• How many linear meters do you expect to cut per week or per month?

• Do you need one versatile blade, or can you stock separate "shop" and "site" blades?

• Are you buying from a retail brand or directly from a manufacturer like SENMINE with OEM options?

Answering these questions helps narrow down the choice from dozens of similar-looking products to a small set of granite saw blades that actually match your needs.

• Can I use the same blade for granite and quartz?

Sometimes, yes. Some premium blades work well on both materials, but performance depends on bond design. If granite is your primary material, choose a granite-tuned blade and treat quartz as a secondary application. For large volumes of both, separate blades usually give better control and longer life.

• Which blade size is best for cutting 2 cm and 3 cm granite?

For 2–3 cm countertops, 4.5"–5" blades on grinders are suitable for trimming and notches, while 10"–14" blades on bridge saws handle the main cuts. Always match diameter and bore to your saw's capacity and guard design, and check the maximum RPM marked on the blade.

• Do I always need water when cutting granite?

For long cuts and high-value edges, you should plan on wet cutting with a wet-rated granite saw blade. Water improves edge quality, extends blade life, and reduces dust. Short, controlled outdoor cuts can be done dry with a proper dry-rated blade and strict heat management, but wet cutting is the safer and more consistent default.

• How often should I replace my granite blade?

Replace a granite blade when cutting speed drops sharply even after dressing, when segments are worn close to the core, or if there are visible cracks, wobble, or segment movement. A good blade choice combined with correct use should give a predictable service life rather than sudden failure.

Choosing the right granite saw blade is about aligning three things: the stone you cut, the machines you use, and the finish your clients expect. Once you understand how granite's hardness and brittleness interact with blade design – segmented, turbo, or continuous rim – it becomes much easier to select blades by logic instead of trial and error. Investing in properly engineered granite saw blades reduces chipping, cuts dust and heat, and saves money over the full life of a project.

If you are planning new granite cutting projects or want to standardize blades across your shop and job sites, it pays to get expert input. Share your material, saw models, and production targets with SENMINE, and our team can recommend a matched granite saw blade solution, including OEM options for distributors and large contractors. Contact Us today to turn this buying guide into a practical plan for cleaner cuts, longer blade life, and more predictable profit on every piece of granite you process.