| Availability: | |

|---|---|

| Quantity: | |

As a segmented diamond core drill designed for wet drilling only, it uses continuous water cooling to stabilize cutting temperature, flush slurry efficiently, and maintain consistent diamond exposure. The result is smoother entry, less glazing, and more repeatable performance across a production run—especially important for distributors and contractors who need stable results from batch to batch.

• Wet-only cutting design

Water cooling reduces friction and heat, improves edge quality, and significantly extends tool life during continuous drilling.

• High-frequency welded diamond segments

Consistent weld strength and segment alignment ensure stable cutting performance in dense concrete and masonry materials.

• Optimized for non-reinforced substrates

Ideal for concrete, brick, block, and stone where steel reinforcement is not present, ensuring smooth penetration and predictable wear.

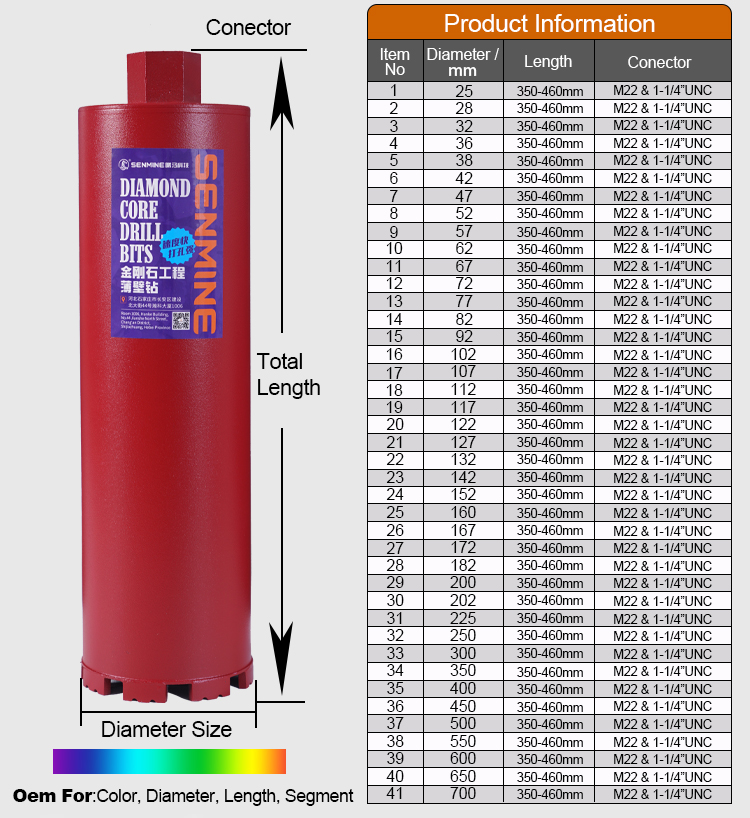

• Universal thread compatibility

Available in M22, 1-1/4" UNC (7 TPI), and 1/2" GAS to fit a wide range of hand-held drills and rig-mounted core machines.

• Wide size coverage

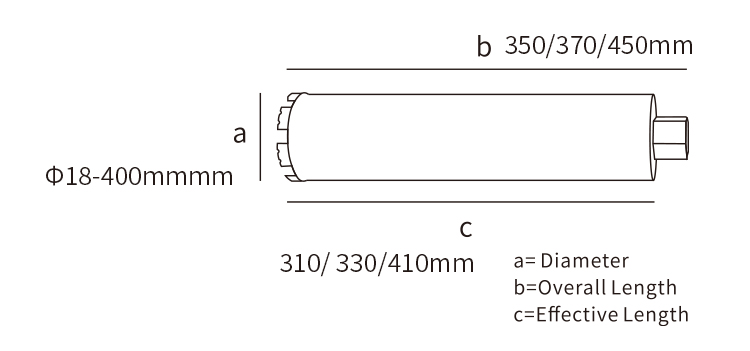

Standard diameters from Ø18–350 mm, with common working lengths of 370 mm and 450 mm. Special sizes available on request.

• Clean, round hole results

Rigid carbon-steel barrels minimize runout, supporting accurate sleeves, anchors, and service penetrations with less post-processing.

• OEM / ODM ready

Custom diameters, bond formulas, colors, laser marking, labels, and packaging supported for brand owners and distributors.

| Diameter (mm) | Diameter (Inch) | Overall length - Effective length (mm) | Diameter (mm) | Diameter (Inch) | Overall length - Effective length (mm) |

|---|---|---|---|---|---|

| Φ18 | 5/7" | 370–330 / 450–410 | Φ108 | 4-1/4" | 370–330 / 450–410 |

| Φ20 | 4/5" | 370–330 / 450–410 | Φ114 | 4-31/64" | 370–330 / 450–410 |

| Φ22 | 7/8" | 370–330 / 450–410 | Φ116 | 4-35/64" | 370–330 / 450–410 |

| Φ25 | 1" | 370–330 / 450–410 | Φ120 | 4-5/7" | 370–330 / 450–410 |

| Φ27 | 1.06" | 370–330 / 450–410 | Φ127 | 5" | 370–330 / 450–410 |

| Φ30 | 1-3/16" | 370–330 / 450–410 | Φ132 | 5-1/5" | 370–330 / 450–410 |

| Φ32 | 1-1/4" | 370–330 / 450–410 | Φ140 | 5-33/64" | 370–330 / 450–410 |

| Φ36 | 1-2/5" | 370–330 / 450–410 | Φ152 | 6" | 370–330 / 450–410 |

| Φ38 | 1-1/2" | 370–330 / 450–410 | Φ159 | 6-3/8" | 370–330 / 450–410 |

| Φ40 | 1-3/5" | 370–330 / 450–410 | Φ162 | 6-25/64" | 370–330 / 450–410 |

| Φ44 | 1-7/10" | 370–330 / 450–410 | Φ168 | 6-3/5" | 370–330 / 450–410 |

| Φ46 | 1-4/5" | 370–330 / 450–410 | Φ180 | 7" | 370–330 / 450–410 |

| Φ51 | 2" | 370–330 / 450–410 | Φ188 | 7-25/64" | 370–330 / 450–410 |

| Φ56 | 2-1/5" | 370–330 / 450–410 | Φ200 | 8" | 370–330 / 450–410 |

| Φ63 | 2-1/2" | 370–330 / 450–410 | Φ220 | 8-7/10" | 370–330 / 450–410 |

| Φ66 | 2-3/5" | 370–330 / 450–410 | Φ230 | 9-1/16" | 370–330 / 450–410 |

| Φ71 | 2-4/5" | 370–330 / 450–410 | Φ245 | 9-3/5" | 370–330 / 450–410 |

| Φ76 | 3" | 370–330 / 450–410 | Φ254 | 10" | 370–330 / 450–410 |

| Φ83 | 3-1/4" | 370–330 / 450–410 | Φ270 | 10-5/8" | 370–330 / 450–410 |

| Φ89 | 3-1/2" | 370–330 / 450–410 | Φ300 | 12" | 370–330 / 450–410 |

| Φ96 | 3-25/32" | 370–330 / 450–410 | Φ325 | 12-51/64" | 370–330 / 450–410 |

| Φ102 | 4" | 370–330 / 450–410 | Φ350 | 14" | 370–330 / 450–410 |

| OEM For: Color, Diameter, Length, Segment | Φ400 | 15-1/2" | 370–330 / 450–410 | ||

Wet core drill bits are primarily used for drilling holes in concrete, rock, asphalt, and other road surfaces.

Examples of typical applications include:

MEP penetrations

• plumbing drain lines and sleeves

• HVAC pipework and AC installation openings

• electrical conduits and fire-protection routing

Infrastructure and municipal work

• highway / bridge utility penetrations

• sewer and pipeline installation

• engineering coring where wet operation is the standard

Retrofit / renovation

• controlled openings through concrete walls and slabs

• minimizing edge breakout that increases patching time

Surface finish is often used for size management and brand consistency—especially when you stock multiple diameters or supply under a private label.

Available options include:

• Spray painting (standard)

• Diameter-based color coding for quick size identification on site and in the warehouse

• Custom colors: black / red / blue / golden / other

• OEM private label support: laser marking and labels

Use & Care Tips

• Always run wet – Ensure steady water flow to the rim; never start the cut dry.

• Rotation-only – Do not use hammer/percussion; it damages segments and increases edge spalling.

• Start square & light – Establish the kerf, then increase feed; periodically lift to clear swarf.

• Dress when needed – If progress slows, dress the rim on an abrasive block to expose fresh diamonds.

Factory & Shipping

Reliable supply isn’t just about tool performance—it’s also about stable production, clean packaging, and repeatable delivery. The images above reflect our typical workflow: raw material storage, semi-finished inventory, production staging, finished goods packing, and palletized outbound shipment.

Factory Capability (Batch Consistency for Repeat Orders)

• Standardized production flow for wet diamond core drill bits: barrel prep → segment welding → finishing → inspection → packing

• Size-program support (multiple diameters in one PO) to match your catalog and stocking plan

• OEM-ready execution for color coding, labels, and cartons to keep your SKU system consistent

Quality Control in Production

• Dimensional checks (diameter, overall length, effective length)

• Thread fit verification (M22 / 1-1/4" UNC) before packing

• Weld integrity inspection to reduce jobsite failures and warranty disputes

• Batch identification for clearer repeat ordering and after-sales tracking

Packaging Options (Choose What Fits Your Channel)

• Standard protection: individual protection + cartons for safe transport

• Bulk packing: efficient for distributors and project supply

• Private label packaging: carton printing, labels, barcodes, model naming alignment

• Export-ready palletizing: shrink wrap + strapping for container or LCL shipments

Shipping & Export Support

• Flexible shipping methods: courier, air freight, sea freight, and forwarder pickup

• Common export documents available: commercial invoice and packing list

• Lead time depends on size list + OEM requirements + order quantity (we’ll confirm in the quotation)

Send your size list + thread + branding needs for a packing & shipping plan.

Why Choose SENMINE

When you’re sourcing a concrete drill bit for wet drilling as a repeatable size program—not a one-off tool—consistency matters as much as cutting performance. SENMINE focuses on stable manufacturing, clear specifications, and OEM-ready execution so your team can stock, sell, and reorder with confidence.

What you get with SENMINE:

• Custom-first supply model: Build your lineup by diameter (Ø18–400 mm), length (370/450 mm), and thread (M22 / 1-1/4" UNC)—then scale it into a long-term program.

• Process-controlled quality: Dimensional checks, thread-fit verification, and weld integrity inspection to reduce mismatch issues and field complaints.

• OEM & private label support: Color coding, marking, labels, and cartons aligned to your SKU system—clean presentation, easier inventory management.

• Export-ready fulfillment: Secure packing, palletizing options, and documentation support for international shipments.

• Responsive technical support: Fast confirmation on thread selection, size planning, and application matching before you place the order.

FAQs

Q1: Is this product only for wet drilling?

Yes. This is a concrete drill bit for wet drilling. Continuous cooling is mandatory for performance and tool life.

Q2: What materials can it drill?

Common applications include concrete, hard masonry/brick, and road/asphalt work (configuration dependent). For mixed materials, request a configuration matched to your jobsite reality.

Q3: What size range do you support?

Standard coverage is Ø18–400 mm, with full diameter mapping available for your catalog and repeat purchasing.

Q4: What are the standard lengths?

Two standard options are 370–330 mm and 450–410 mm (overall–effective). Custom lengths can be discussed for project needs.

Q5: Which threads do you offer?

Common options include M22 and 1-1/4" UNC. If your region uses different standards, provide the spindle/thread requirement and we’ll confirm.

Q6: Can I order this as a private label product?

Yes. OEM options include color customization, marking, labels, and packaging for distributor programs.

Q7: How do I choose between speed and lifespan configurations?

Tell us your priority: faster penetration for time-sensitive work, or longer service life for cost control. We’ll recommend a configuration based on your material abrasiveness.

Q8: What’s your MOQ for custom orders?

Typically 10 pieces per product as a starting MOQ, depending on size and configuration.

Q9: Can you help us build a full size program for distribution?

Yes. Many buyers purchase this as a diameter program (best sellers + long-tail sizes) with consistent colors, labeling, and documentation.

Q10: What information do you need to quote fast?

Diameter list, length, thread, material type, and branding requirements. The more complete your RFQ, the faster the quotation and production alignment.

As a segmented diamond core drill designed for wet drilling only, it uses continuous water cooling to stabilize cutting temperature, flush slurry efficiently, and maintain consistent diamond exposure. The result is smoother entry, less glazing, and more repeatable performance across a production run—especially important for distributors and contractors who need stable results from batch to batch.

• Wet-only cutting design

Water cooling reduces friction and heat, improves edge quality, and significantly extends tool life during continuous drilling.

• High-frequency welded diamond segments

Consistent weld strength and segment alignment ensure stable cutting performance in dense concrete and masonry materials.

• Optimized for non-reinforced substrates

Ideal for concrete, brick, block, and stone where steel reinforcement is not present, ensuring smooth penetration and predictable wear.

• Universal thread compatibility

Available in M22, 1-1/4" UNC (7 TPI), and 1/2" GAS to fit a wide range of hand-held drills and rig-mounted core machines.

• Wide size coverage

Standard diameters from Ø18–350 mm, with common working lengths of 370 mm and 450 mm. Special sizes available on request.

• Clean, round hole results

Rigid carbon-steel barrels minimize runout, supporting accurate sleeves, anchors, and service penetrations with less post-processing.

• OEM / ODM ready

Custom diameters, bond formulas, colors, laser marking, labels, and packaging supported for brand owners and distributors.

| Diameter (mm) | Diameter (Inch) | Overall length - Effective length (mm) | Diameter (mm) | Diameter (Inch) | Overall length - Effective length (mm) |

|---|---|---|---|---|---|

| Φ18 | 5/7" | 370–330 / 450–410 | Φ108 | 4-1/4" | 370–330 / 450–410 |

| Φ20 | 4/5" | 370–330 / 450–410 | Φ114 | 4-31/64" | 370–330 / 450–410 |

| Φ22 | 7/8" | 370–330 / 450–410 | Φ116 | 4-35/64" | 370–330 / 450–410 |

| Φ25 | 1" | 370–330 / 450–410 | Φ120 | 4-5/7" | 370–330 / 450–410 |

| Φ27 | 1.06" | 370–330 / 450–410 | Φ127 | 5" | 370–330 / 450–410 |

| Φ30 | 1-3/16" | 370–330 / 450–410 | Φ132 | 5-1/5" | 370–330 / 450–410 |

| Φ32 | 1-1/4" | 370–330 / 450–410 | Φ140 | 5-33/64" | 370–330 / 450–410 |

| Φ36 | 1-2/5" | 370–330 / 450–410 | Φ152 | 6" | 370–330 / 450–410 |

| Φ38 | 1-1/2" | 370–330 / 450–410 | Φ159 | 6-3/8" | 370–330 / 450–410 |

| Φ40 | 1-3/5" | 370–330 / 450–410 | Φ162 | 6-25/64" | 370–330 / 450–410 |

| Φ44 | 1-7/10" | 370–330 / 450–410 | Φ168 | 6-3/5" | 370–330 / 450–410 |

| Φ46 | 1-4/5" | 370–330 / 450–410 | Φ180 | 7" | 370–330 / 450–410 |

| Φ51 | 2" | 370–330 / 450–410 | Φ188 | 7-25/64" | 370–330 / 450–410 |

| Φ56 | 2-1/5" | 370–330 / 450–410 | Φ200 | 8" | 370–330 / 450–410 |

| Φ63 | 2-1/2" | 370–330 / 450–410 | Φ220 | 8-7/10" | 370–330 / 450–410 |

| Φ66 | 2-3/5" | 370–330 / 450–410 | Φ230 | 9-1/16" | 370–330 / 450–410 |

| Φ71 | 2-4/5" | 370–330 / 450–410 | Φ245 | 9-3/5" | 370–330 / 450–410 |

| Φ76 | 3" | 370–330 / 450–410 | Φ254 | 10" | 370–330 / 450–410 |

| Φ83 | 3-1/4" | 370–330 / 450–410 | Φ270 | 10-5/8" | 370–330 / 450–410 |

| Φ89 | 3-1/2" | 370–330 / 450–410 | Φ300 | 12" | 370–330 / 450–410 |

| Φ96 | 3-25/32" | 370–330 / 450–410 | Φ325 | 12-51/64" | 370–330 / 450–410 |

| Φ102 | 4" | 370–330 / 450–410 | Φ350 | 14" | 370–330 / 450–410 |

| OEM For: Color, Diameter, Length, Segment | Φ400 | 15-1/2" | 370–330 / 450–410 | ||

Wet core drill bits are primarily used for drilling holes in concrete, rock, asphalt, and other road surfaces.

Examples of typical applications include:

MEP penetrations

• plumbing drain lines and sleeves

• HVAC pipework and AC installation openings

• electrical conduits and fire-protection routing

Infrastructure and municipal work

• highway / bridge utility penetrations

• sewer and pipeline installation

• engineering coring where wet operation is the standard

Retrofit / renovation

• controlled openings through concrete walls and slabs

• minimizing edge breakout that increases patching time

Surface finish is often used for size management and brand consistency—especially when you stock multiple diameters or supply under a private label.

Available options include:

• Spray painting (standard)

• Diameter-based color coding for quick size identification on site and in the warehouse

• Custom colors: black / red / blue / golden / other

• OEM private label support: laser marking and labels

Use & Care Tips

• Always run wet – Ensure steady water flow to the rim; never start the cut dry.

• Rotation-only – Do not use hammer/percussion; it damages segments and increases edge spalling.

• Start square & light – Establish the kerf, then increase feed; periodically lift to clear swarf.

• Dress when needed – If progress slows, dress the rim on an abrasive block to expose fresh diamonds.

Factory & Shipping

Reliable supply isn’t just about tool performance—it’s also about stable production, clean packaging, and repeatable delivery. The images above reflect our typical workflow: raw material storage, semi-finished inventory, production staging, finished goods packing, and palletized outbound shipment.

Factory Capability (Batch Consistency for Repeat Orders)

• Standardized production flow for wet diamond core drill bits: barrel prep → segment welding → finishing → inspection → packing

• Size-program support (multiple diameters in one PO) to match your catalog and stocking plan

• OEM-ready execution for color coding, labels, and cartons to keep your SKU system consistent

Quality Control in Production

• Dimensional checks (diameter, overall length, effective length)

• Thread fit verification (M22 / 1-1/4" UNC) before packing

• Weld integrity inspection to reduce jobsite failures and warranty disputes

• Batch identification for clearer repeat ordering and after-sales tracking

Packaging Options (Choose What Fits Your Channel)

• Standard protection: individual protection + cartons for safe transport

• Bulk packing: efficient for distributors and project supply

• Private label packaging: carton printing, labels, barcodes, model naming alignment

• Export-ready palletizing: shrink wrap + strapping for container or LCL shipments

Shipping & Export Support

• Flexible shipping methods: courier, air freight, sea freight, and forwarder pickup

• Common export documents available: commercial invoice and packing list

• Lead time depends on size list + OEM requirements + order quantity (we’ll confirm in the quotation)

Send your size list + thread + branding needs for a packing & shipping plan.

Why Choose SENMINE

When you’re sourcing a concrete drill bit for wet drilling as a repeatable size program—not a one-off tool—consistency matters as much as cutting performance. SENMINE focuses on stable manufacturing, clear specifications, and OEM-ready execution so your team can stock, sell, and reorder with confidence.

What you get with SENMINE:

• Custom-first supply model: Build your lineup by diameter (Ø18–400 mm), length (370/450 mm), and thread (M22 / 1-1/4" UNC)—then scale it into a long-term program.

• Process-controlled quality: Dimensional checks, thread-fit verification, and weld integrity inspection to reduce mismatch issues and field complaints.

• OEM & private label support: Color coding, marking, labels, and cartons aligned to your SKU system—clean presentation, easier inventory management.

• Export-ready fulfillment: Secure packing, palletizing options, and documentation support for international shipments.

• Responsive technical support: Fast confirmation on thread selection, size planning, and application matching before you place the order.

FAQs

Q1: Is this product only for wet drilling?

Yes. This is a concrete drill bit for wet drilling. Continuous cooling is mandatory for performance and tool life.

Q2: What materials can it drill?

Common applications include concrete, hard masonry/brick, and road/asphalt work (configuration dependent). For mixed materials, request a configuration matched to your jobsite reality.

Q3: What size range do you support?

Standard coverage is Ø18–400 mm, with full diameter mapping available for your catalog and repeat purchasing.

Q4: What are the standard lengths?

Two standard options are 370–330 mm and 450–410 mm (overall–effective). Custom lengths can be discussed for project needs.

Q5: Which threads do you offer?

Common options include M22 and 1-1/4" UNC. If your region uses different standards, provide the spindle/thread requirement and we’ll confirm.

Q6: Can I order this as a private label product?

Yes. OEM options include color customization, marking, labels, and packaging for distributor programs.

Q7: How do I choose between speed and lifespan configurations?

Tell us your priority: faster penetration for time-sensitive work, or longer service life for cost control. We’ll recommend a configuration based on your material abrasiveness.

Q8: What’s your MOQ for custom orders?

Typically 10 pieces per product as a starting MOQ, depending on size and configuration.

Q9: Can you help us build a full size program for distribution?

Yes. Many buyers purchase this as a diameter program (best sellers + long-tail sizes) with consistent colors, labeling, and documentation.

Q10: What information do you need to quote fast?

Diameter list, length, thread, material type, and branding requirements. The more complete your RFQ, the faster the quotation and production alignment.